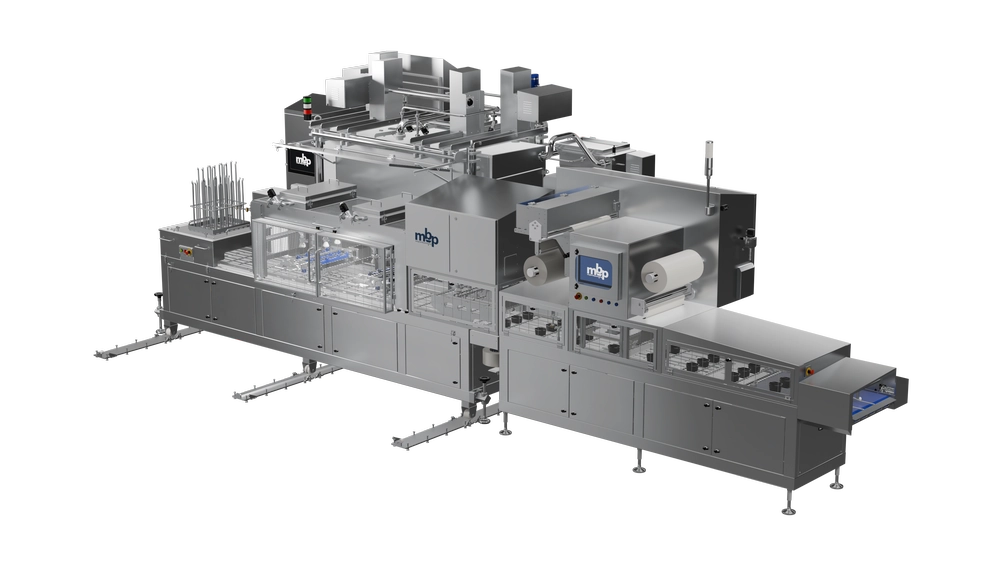

Packaging machine for mozzarella and burrata

MBP DeliX-B

Automated burrata: efficiency, hygiene and accuracy thanks to the Mozzamatic + MBT-PFM integrated line.

Automated burrata:

setting a new standard for dairy excellence.

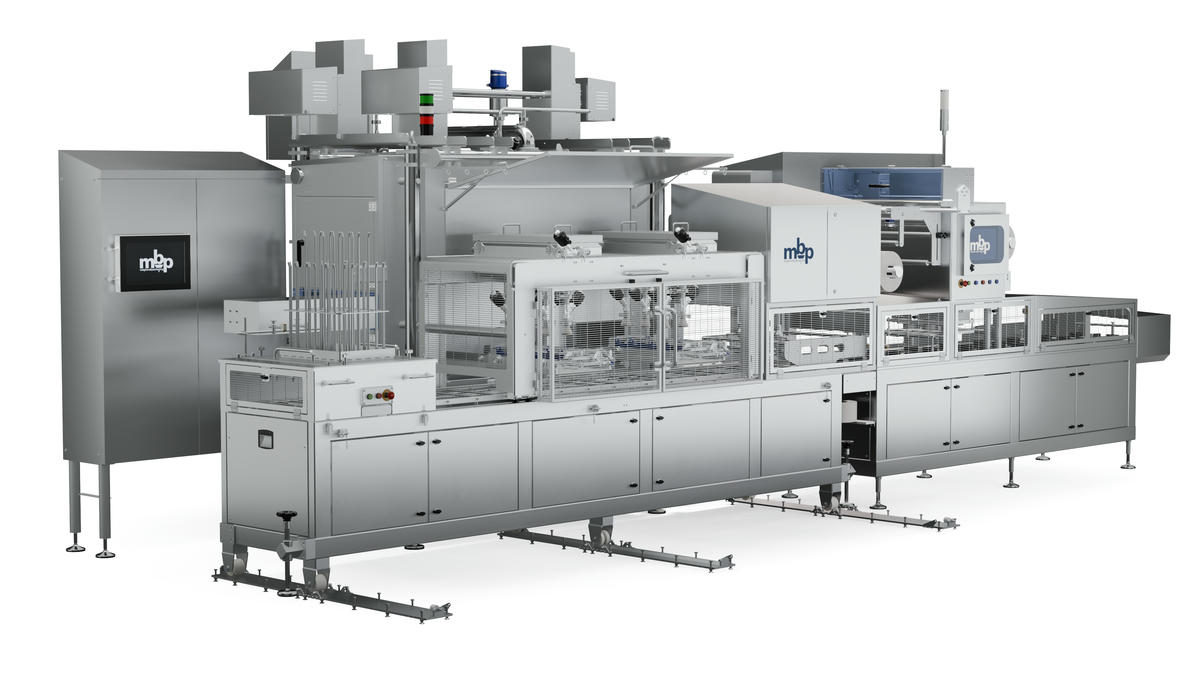

Mozzamatic + MBP-PFM: tradition and innovation come together in a single integrated line. The leap from local excellence in the Apulia region to becoming a leading player in the international chilled products sector was made possible by a production evolution that combines technological innovation with respect for artisanal tradition.

Main Benefits

Extended shelf life

The product undergoes continuous processing in a controlled environment, which guarantees a shelf life and consistent organoleptic and microbiological results. This feature makes the line ideal for producers looking to export to distant markets or operate within the international mass retail sector.

Accuracy and artisan quality

The system is equipped with advanced quality control technologies, including weight control for each individual burrata placed in the tray, automatic rejection of underweight or damaged burrata, a stainless steel structure that is easy to sanitise, and container presence control with block in case of missing product.

High-speed efficiency

Reliable, flexible packaging suitable for various formats, with a capacity of over 3,000 pieces per hour. Real-time interaction between production and packaging ensures consistent quality parameters, thereby increasing the plant’s overall efficiency.

From a tender heart to the pack:

a continuous flow of burrata

Each burrata is produced in complete isolation from the operator, in fully hygienic and controlled conditions, with a production capacity of over 3,000 pieces, regardless of format. Thanks to two movable dosing stations, each equipped with six injectors, the process takes place in a synchronous and continuous manner. These stations can handle high volumes without compromising the quality of the product.

Features

- The weight of every burrata placed in the tray is checked in real time.

- Non-conforming products are rejected automatically.

- 1 or 2 burrata per tray.

- Fully washable IP69

- 3,000 pieces/hour.