Innovation & Design

Multi-head weigher performance relies on correct choice and perfect operation of the large number of mechanical, software and hardware components to give accuracy, safety over time, and guaranteed hygiene.

The ten major assets of MBP weighers can be summarized as below:

Vibrating (or rotating) central plate equipped with load cell to maintain a consistent quantity of product available and guarantee optimum distribution of the product over the surrounding channels. The Vibcontrol system maintains a constant vibrating capacity regardless of the amount of product present.

Perfect operation and control of the vibrating bases, which reduce weight regeneration times to a minimum.

New generation load cells with temperature compensation systems featuring extremely high speeds and highly accurate weighing.

Extremely efficient automatic environment vibration annulment system to prevent vibrations interfering with and altering digital weighing data. The system works in real time and is extremely precise.

High speed opening/closing of pre-dosing and weighing buckets (0.15 tenths of a second) with acceleration/deceleration ramps adjustable to suit the product.

Highly developed software that consists of a wide range of combination calculation and automatic control functions operating in real time for all the machine’s parameters. These adapt to changing products and working environments.

High capacity, real time CAN-Open type hardware architecture. Electromagnetic interference annulment system; secondary functions can be decentralised with the advantage of reducing the time taken from data collection to processing to a minimum. Can be connected to the outside world in multimedia form.

Prime quality AISI 304 tubular stainless steel support frame with rounded corners. Easily accessible, single, dehumidified electronic control panel that complies with international safety regulations.

Powerful, stable processor that guarantees high performance with real-time control of all machine processes.

Constant control over relative humidity inside the machine to ensure greater stability of the hardware and mechanical components, with the added advantage of lengthening the life of components.

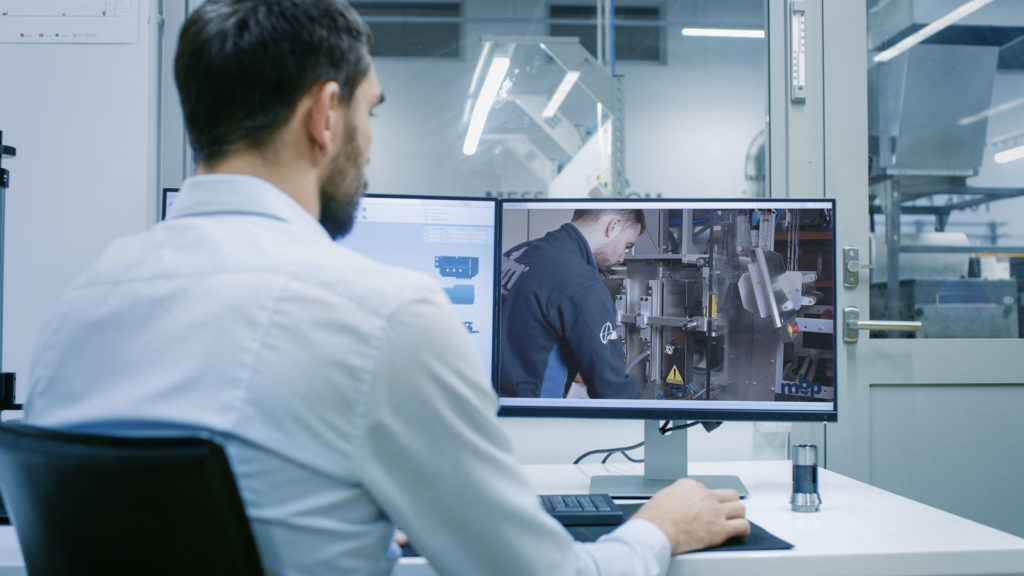

MBP Research & Development

Research and development is the heart of MBP and is supported by an annual 10 per cent of turnover. The MBP research centre also collaborates on an ongoing basis with leading Italian and European universities.

MBP’s development program is organized though the division of research into sections, each assigned to highly qualified research scientists. Research covers all the strategic points involved in a weigher working properly.

This means that MBP is continuously experimenting with innovation in all the mechanical, hardware and software aspects of weighers. The best of these are selected, tested, checked and then made available to the most demanding customers. The Series C1, C2, C3 and C4 are the results of this method of working.