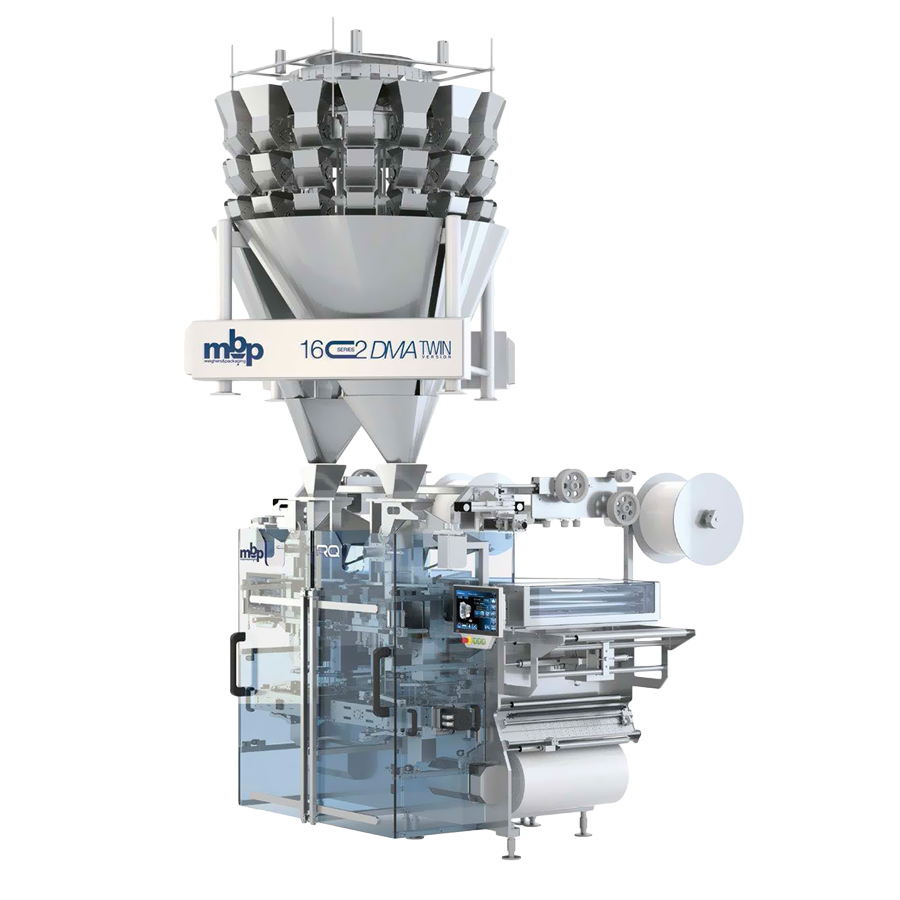

Vertical Packaging Machines

MBP RQ700 TWIN

Intermittent, Single-reel, Doy-Style removable sealing unit.

R-evolutionary VFFS Wrappers

Intermittent Doy-Style

RQ700 TWIN is an intermittent motion VFFS machine to produce pillow-bags, square-bottom bags, Steelo-bags and Doy-Style bags.

RQ700 contains all the features of R-Series plus the benefits deriving from the QRM POWER FEEDBACK interchangeable, removable, rotatable sealing unit.

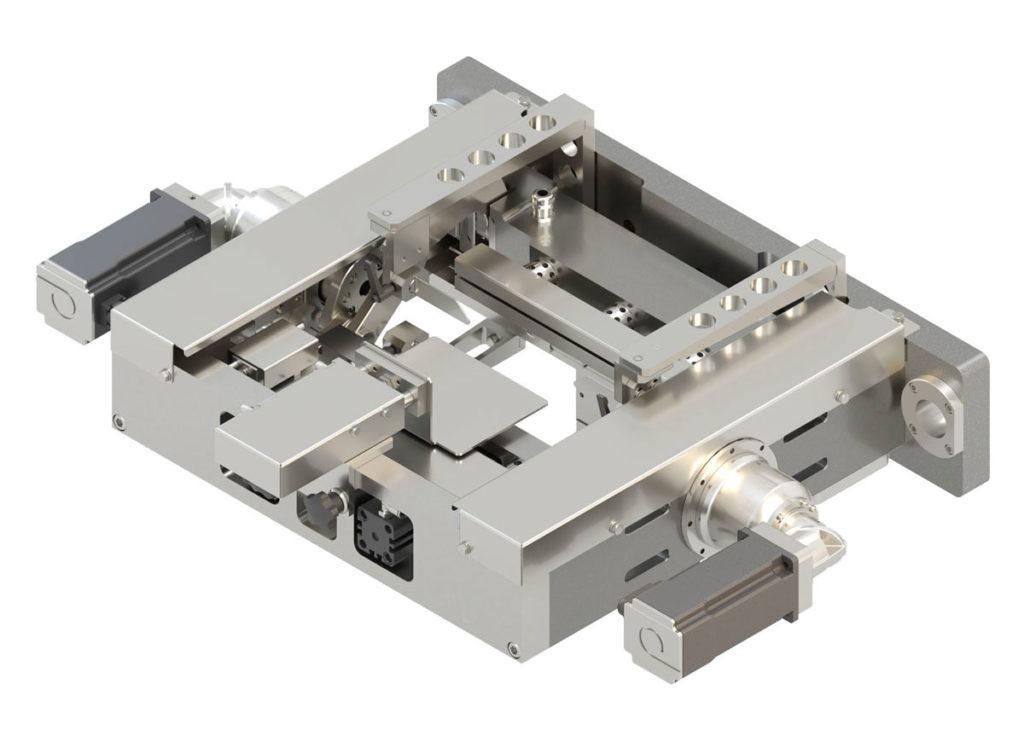

MBP QRM POWER FEEDBACK

XTRACT – ROTATE – CHANGE

QRM Quick Release Module (sealing Group): the new concept of sealing unit interchangeable, removable, rotatable.

To change format from pillow bag or Steelo bag to Doy-style just pull out the first QRM sealing unit and insert the second one (optional), rotated 90°.

QRM is also equipped with motors to activate clamps, bellows and all necessary devices for each type of packaging. In short, the QRM sealing device can:

- Reduce the time to change format.

- Improve the quality of the packaging.

- Increase the wrapping speed.

Top Performance and

Smaller Overall Dimensions

Doy Style R-Series’ technology guarantees top performance and smaller overall dimensions.

The TWIN configuration allows double production using one MBP multi-head weigher, even in small places.

- RQ700 TWIN occupies 3,2 m² and features a 700 mm film width.

- Intermittent version pillow-bag output up to 120+120 packs/min.

- Production with square bottom and/or Steelo-Bag can reach up to 60+60 packs/min with one outfeed conveyor.

- Three side seal bags output can reach up to 60+60 packs/min with one outfeed conveyor.

- Doy-Style output can reach up to 60+60 packs/min with one outfeed conveyor.

- The time needed to change the format is halved compared to any continuous machine model.

- 50% of the production is always guaranteed. If the potential is not exploited to its maximum, it is possible to increase line production so as to compensate for a stopped line.

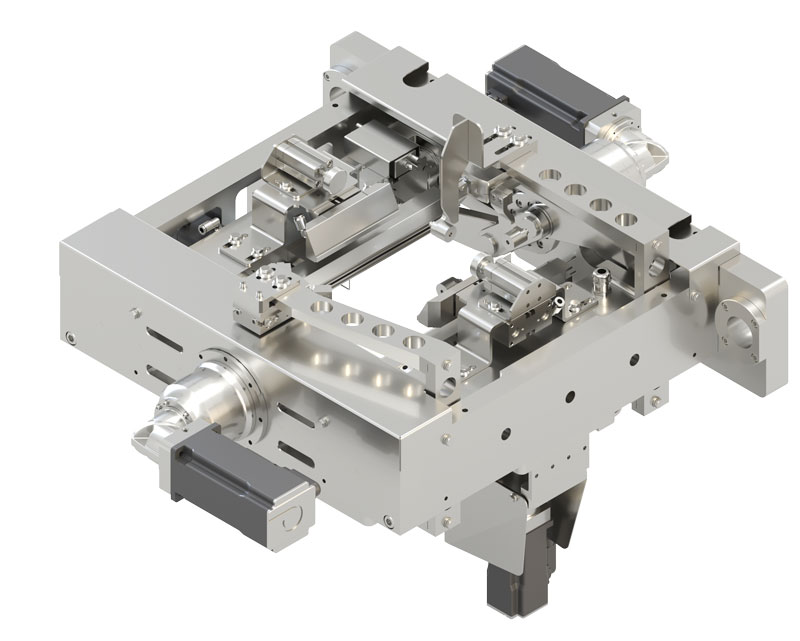

RQ700 ECO-FILM

A New Dimension in Sustainable Packaging

The RQ700 Eco-Film is designed to use mono-film, or recyclable film laminated with paper, even of high thickness. Depending on the film, the machine can produce up to 120 pillow bags per minute and up to 60 square bottom bags per minute.

Advantages:

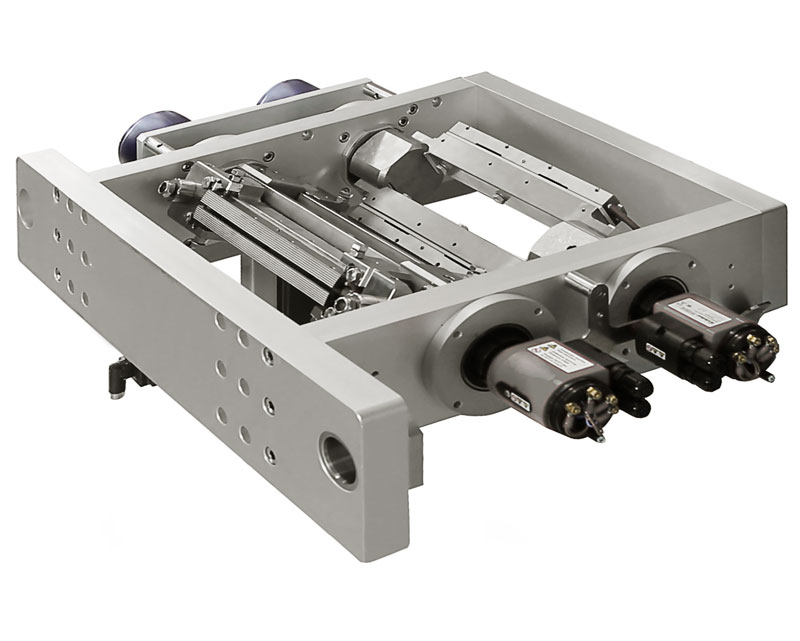

- Unique transverse sealing unit with high sealing pressure and integrated measurement of the applied force. The sealing force is measured on the left and right side of the sealing jaw allowing perfect balancing. The sealing unit (QRM) can be removed in 3 minutes with a simple trolley supplied.

- Innovative film unwinding system with only 6 rolls, with a motorized reel-holder shaft that reduces film stretching, optimizing unwinding control.

- The film-turning triangle keeps the film centered to a tenth of a mm in relation to the forming tube, ensuring perfectly symmetrical seals.

The RQ700 Eco-Film produces three-seal bags, but also square bottom and 4-seal bags.

Packages Produced

Pillow Bag

- W: 70-320mm

- L: 60-400mm

- Up to 400 bags/min QRM Rotative (cutting pitch up to 150 mm)

Gusseted Bag

- W: 70-320mm

- D: 60-400mm

- Up to 400 bags/min QRM Rotative (cutting pitch up to 150 mm)

Block Bottom

- W: 90-180mm

- D: 50-100mm

- L: 100-380mm

- Up to 120 bags/min

Steelo-Bag Sided Seal

- W: 90-180mm

- D: 55-120mm

- L: 100-350mm

- Up to 140 bags/min

3-sided

3-sided Zip

- W: 90-250mm

- L: 60-220mm

- Up to 130 bags/min

- Feed direction 90° rotated

Doy-Style

Doy-Style with Zip

- W: 90-150mm

- L: 70-220mm

- Up to 120 bags/min

- Feed direction 90° rotated