Multihead weighers

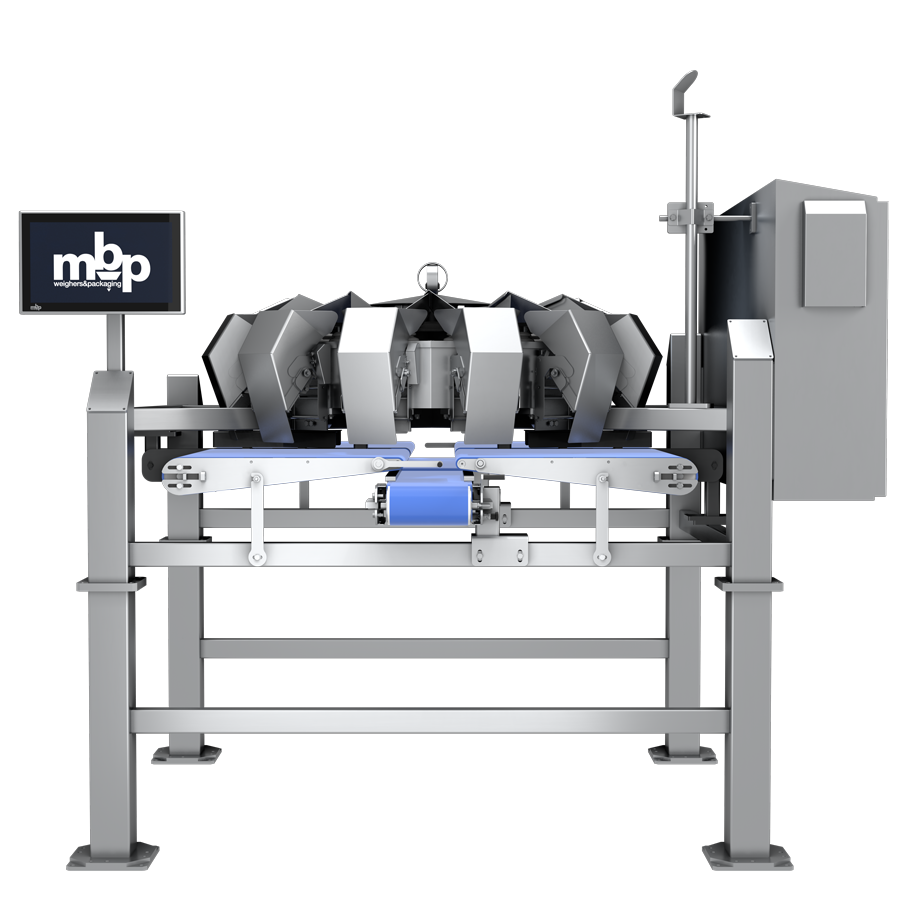

MBP C4 Series

Designed for high speed precision weighing with fragile and delicate products.

HIGH SPEED FOR FRAGILE PRODUCTS

MBP Multihead Weighers presents the new range of Series C4 multihead weighers, which are successfully launching the company into the high speed precision weighing sector for fragile and delicate products.

Weighable Products

Top Class Features

Mechanical and Technical

- Removable and interchangeable modules.

- Load cell on central base.

- Easily cleanable smooth structure with no hidden crevices.

- Vibrating bases with optimum, precise vibration angles.

- Tubular AISI 304 steel frame with single electronic control panel. Easy to clean and disinfect, fast removal of moving parts.

- IP54 protection rating.

- Operated through an industrial PC.

- CAN-Open type wiring network protected against electromagnetic interference, modular, with fast, high-capacity data transmission.

- Multimedia software based on Windows, which can be controlled remotely. Parameter setting reduced to just three sets of data. The remaining parameters are entered by means of highly developed automatic real time functions.

Small Product Drop Height

Perfect for Fragile Products

Underneath the weighing baskets, four conveyor belts transport the weighed product to another two belts, which then transport it to the central discharge point. The drop height is just 40mm.

Advanced software

and easy programming

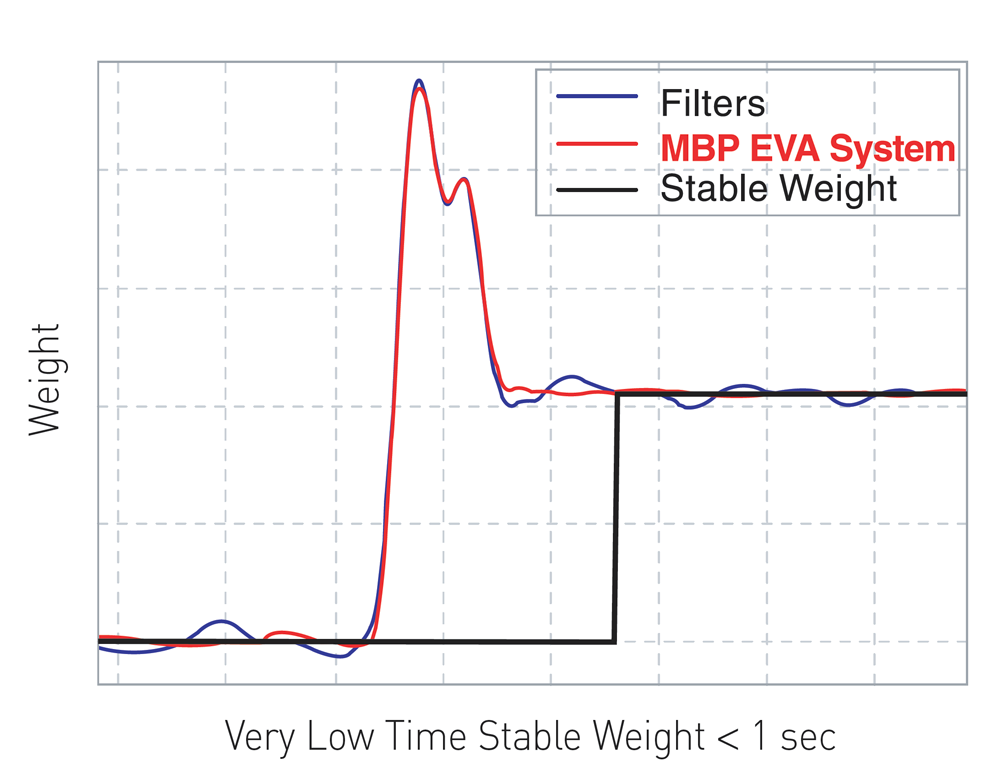

The AVC, ARC, ADC and EVA systems, together with the Vib-control device (if present), operate simultaneously. These software functions are highly advanced and make programming the machine really easy. The operator sets the target weight, top/lower limits, the production speed parameters and the weight of the central plate. The weigher automatically adjusts:

- The best amplitude and time of vibration for each vibrating channel. The adjustment takes place continuously.

- Diversification of the best quantity of product discharged into the various pre-dosing buckets.

- Ideal number of buckets used for discharging.

The weigher adapts to the product and the working environment in real time. Once learned, the machine data are systematically stored in the specific recipe. This guarantees perfect efficiency of the weigher at all times.